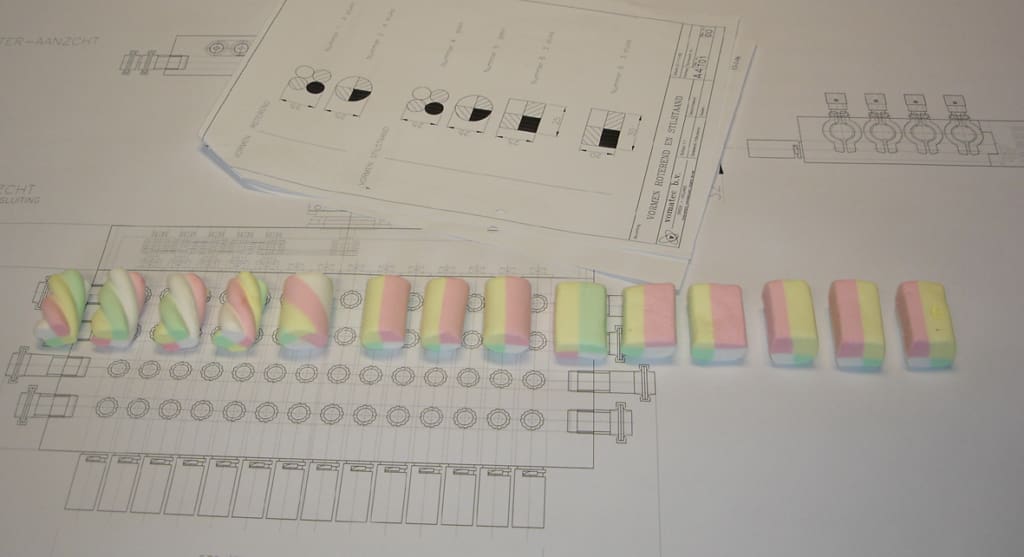

Perfect marshmallow shapes

Endless

Precision

Center

Frequently Asked Questions

Feel free to contact us.

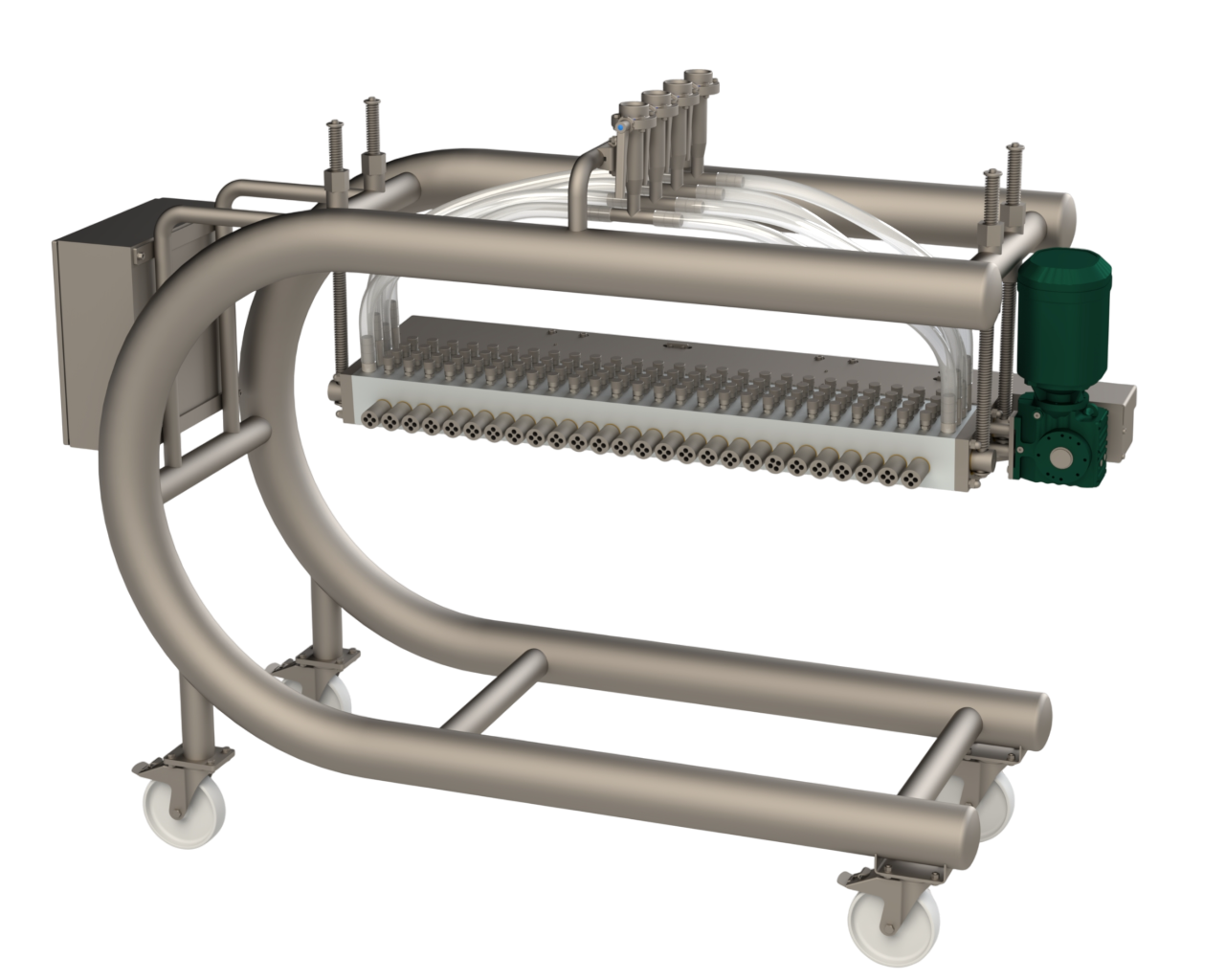

The VomaEXTRUDER can handle a wide range of marshmallow formats, including ropes, twisted strands, layered shapes, and co-extruded filled profiles. It is designed for stable extrusion of aerated masses, even with complex geometries.

The final shape depends on the type of nozzle used and whether the extruder is configured for static or dynamic (rotating) extrusion. Both options are available, depending on your product requirements.

Yes. The VomaEXTRUDER can be fitted with custom-designed nozzles to produce a wide variety of shapes and profiles. We offer both FDA-compliant 3D-printed plastic nozzles for prototyping and production, as well as 3D-printed stainless steel (316) nozzles for long-term industrial use. This allows for full flexibility in shape design from standard ropes to highly customized marshmallow formats.

Precision and flexibility

The VomaEXTRUDER is designed for consistent shaping of marshmallow products from standard ropes to multi-color, twisted, or center-filled forms. The system delivers clean, defined results with a stable product flow, aerated masses.

Its modular setup supports both static and dynamic extrusion. It can be configured fully static, fully dynamic, or split — allowing static and rotating nozzles to run simultaneously. Depending on your product design, the extruder can be fitted with 3D-printed plastic or stainless steel (SS 316) nozzles.

Quick shape changeovers and clean output make the VomaEXTRUDER a reliable choice for manufacturers looking for shape flexibility without compromising line stability.

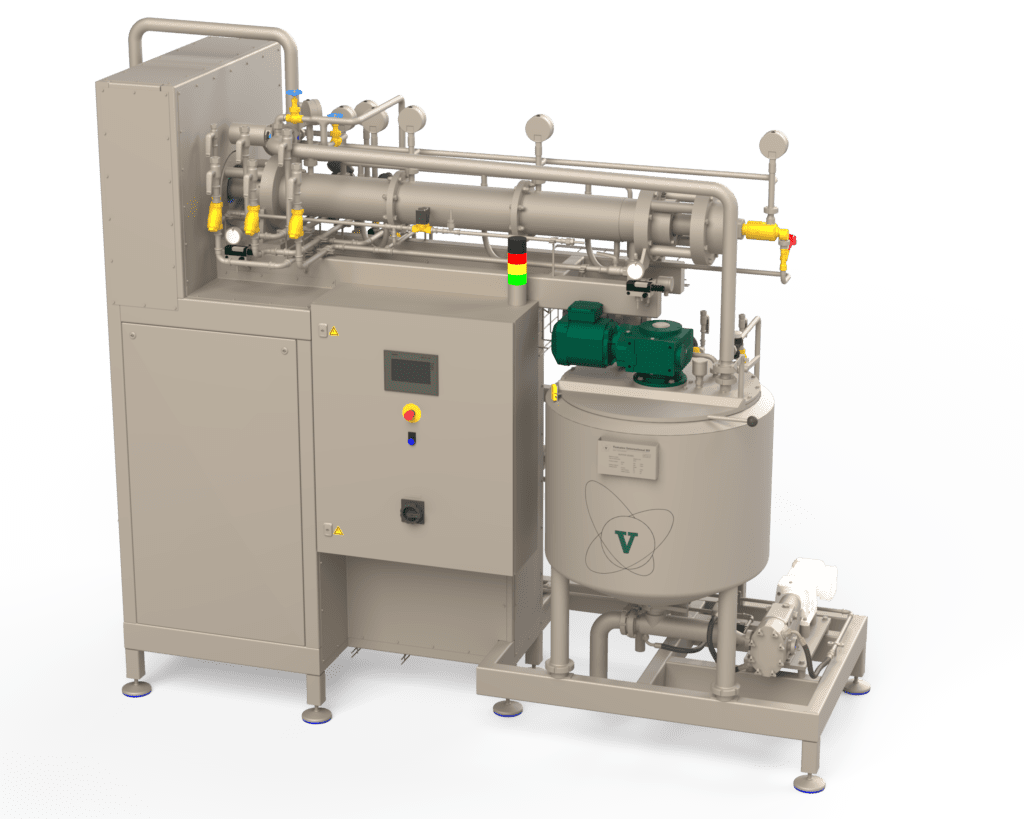

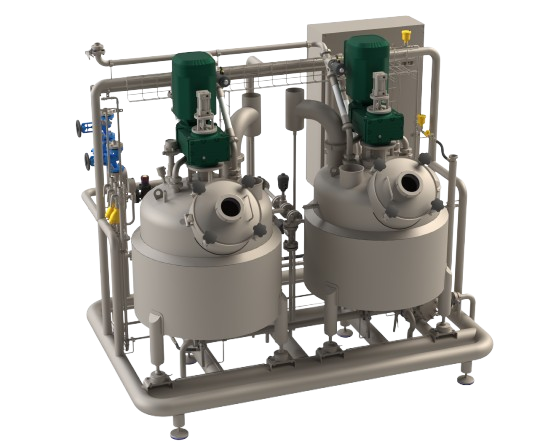

Other machines

The VomaEXTRUDER is a high-precision marshmallow extrusion system designed for clean shaping of aerated products. It handles a wide range of marshmallow formats, from classic ropes and twisted strands to layered and co-extruded filled profiles.

The system supports both static and dynamic (rotating) extrusion and can be configured in multiple ways — including full static, full dynamic, or a hybrid setup where part of the product is extruded statically and the other part dynamically. Custom nozzles, including FDA-compliant plastic and 3D-printed stainless steel (S 316), allow complete freedom in shape, structure, and color separation.

Designed for consistent flow and stable output, the VomaEXTRUDER integrates directly after your aeration system. It minimizes deformation, enables fast changeovers, and supports single-color, multi-color, and center-filled formats — all with clean definition and repeatable results.

For confectionery producers looking to improve product definition, reduce waste, and gain more flexibility in marshmallow shaping, the VomaEXTRUDER offers a modular, future-ready solution for continuous production.