Cooling & Crystallizing

Specials

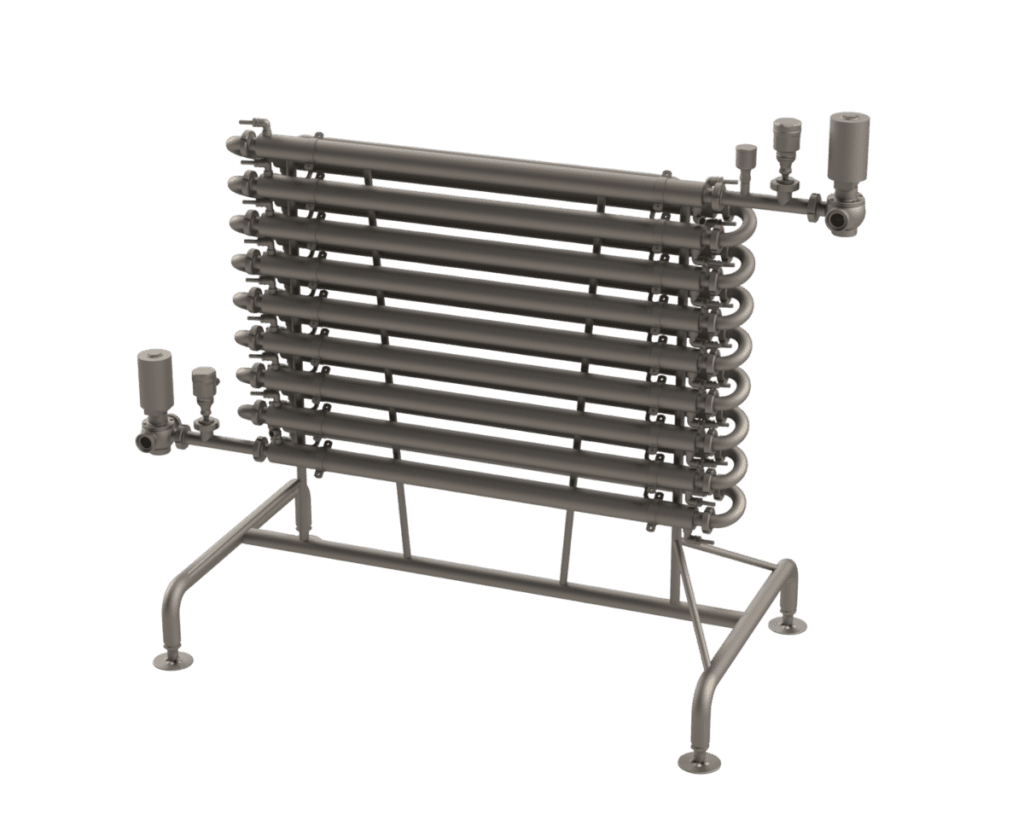

Cooling tables

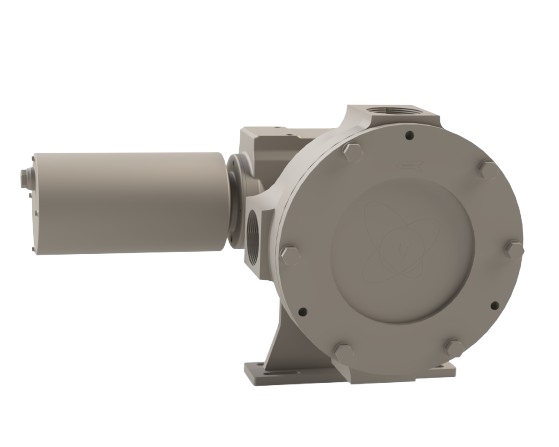

VomaRC

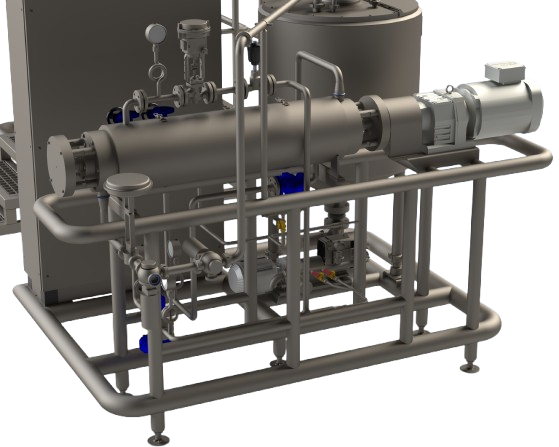

VomaTEMP

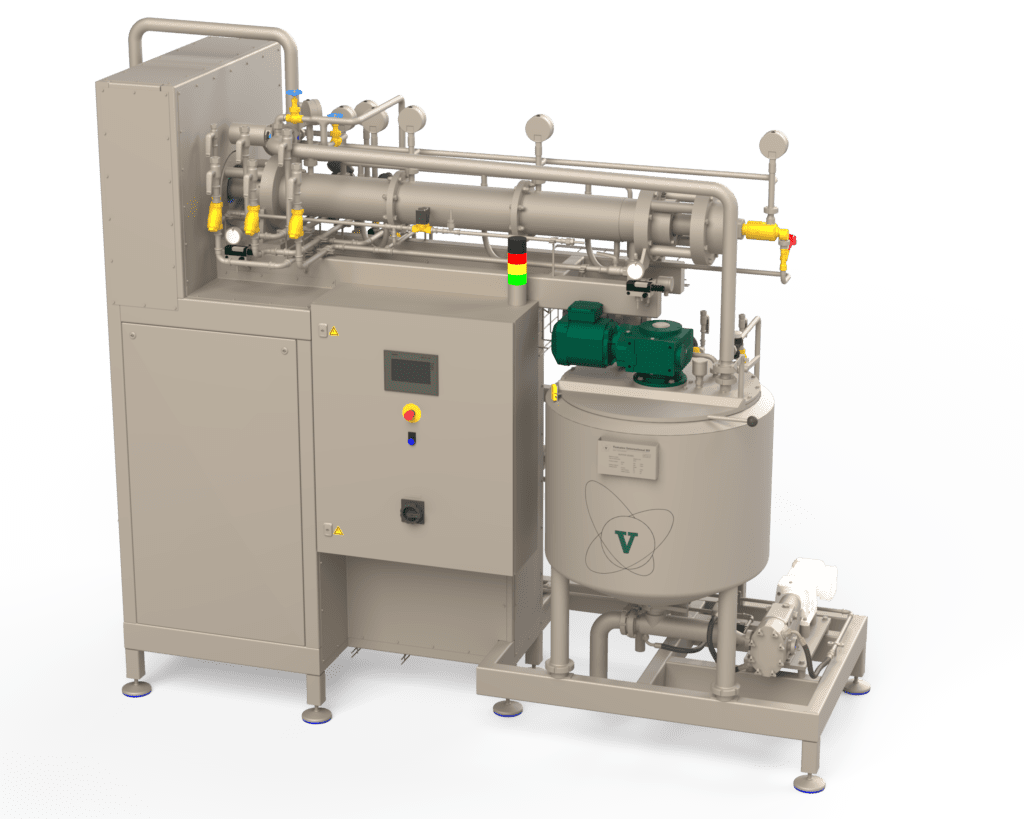

VomaTAB

Cooling & Crystallizing:

Cooling & Crystallizing

Precision That Shapes the Final Product

Cooling and crystallization define the texture, structure, and bite of many confectionery products. From soft jellies to aerated masses and sugar-based fillings, this step determines how the product sets, handles, and performs after forming.

Traditional methods like tray cooling or open-table setups offer limited control and often lead to variation. Today’s cooling systems must deliver stable, repeatable results while supporting hygiene and process efficiency.

Core Benefits

- Optimized Texture & Crystallization: Prevents unwanted stickiness, graininess, or structural defects by maintaining precise temperature curves.

- Consistent Product Quality: Ensures repeatable cooling cycles, reducing batch-to-batch variations.

- Scalability & Efficiency: Designed for both small-batch R&D and full-scale industrial production.

Engineered for Cooling Performance

Vomatec designs cooling and crystallization systems that prioritize thermal control, hygiene and product integrity. From jacketed pipe systems to flat cooling surfaces, every solution is built for clean operation and minimal product stress.

Whether you’re stabilizing a sugar mass, setting a whipped foam, or crystallizing fondant, Vomatec gives you the control and consistency needed to shape quality products — efficiently and reliably.