storage

Specials

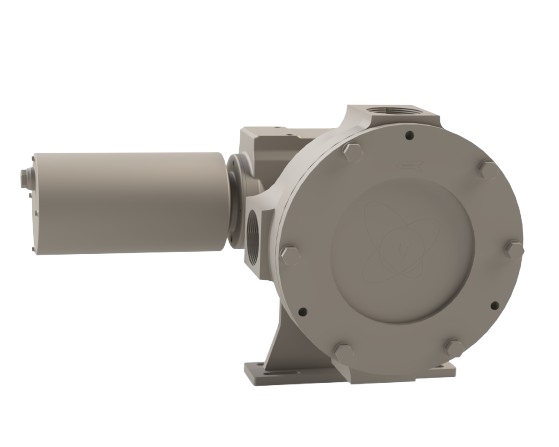

Glucose tank

Storage:

From Small-Scale Solutions to Large-Capacity Efficiency

In confectionery production, ingredient storage is more than holding capacity — it’s a critical part of process reliability. Liquid ingredients like glucose syrup must remain stable, available on demand, and protected from contamination. Any interruption in flow or temperature variation can disrupt downstream processes.

Modern storage systems are engineered to ensure precise temperature control, hygienic design, and seamless integration with cooking or mixing steps. Whether in pilot environments or full-scale lines, reliable storage supports smooth, efficient production.

Core Benefits

- Consistent Supply: Ensures a continuous flow of glucose syrup to the production line, preventing process interruptions.

- Hygienic Design: Tanks are constructed with food-grade materials and CIP-ready (Clean-In-Place) systems for optimal hygiene.

- Capacity Flexibility: Options available for both small-capacity pilot plants and large-scale production environments.

Designed Around Your Process

Vomatec develops storage systems that fit your workflow — from compact, temperature-stabilized vessels to large tanks with heating jackets and integrated controls. Each tank is designed for reliability, cleanability, and easy connection to upstream and downstream equipment.

With Vomatec, you gain more than storage — you gain a stable foundation for consistent production.