Gentle surface cleaning

Non-Contact

Hygienic

Compact

Frequently Asked Questions

Feel free to contact us.

Clean finish, no compromise

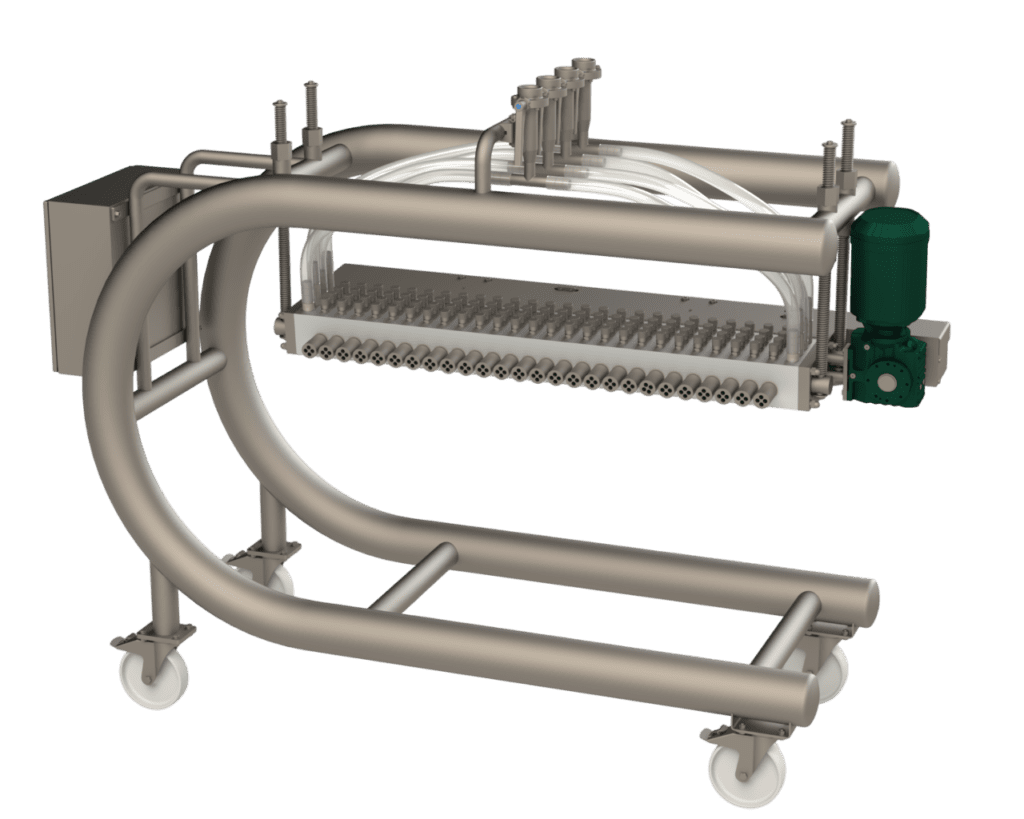

The VomaCLEAN ensures that your candy leaves the molding stage free of starch, sugar or powder without friction or surface damage. Instead of brushes, the system uses powerful air spinners to gently remove residues. This prevents abrasion, sticking and product loss.

The unit is made entirely of stainless steel, fully accessible and easy to clean. Its compact footprint makes it suitable for both pilot-scale and industrial production lines.

Designed for soft, molded confectionery, the VomaCLEAN improves product appearance and reduces manual handling. It is a clean and efficient step that saves time, reduces waste and keeps your process consistent.

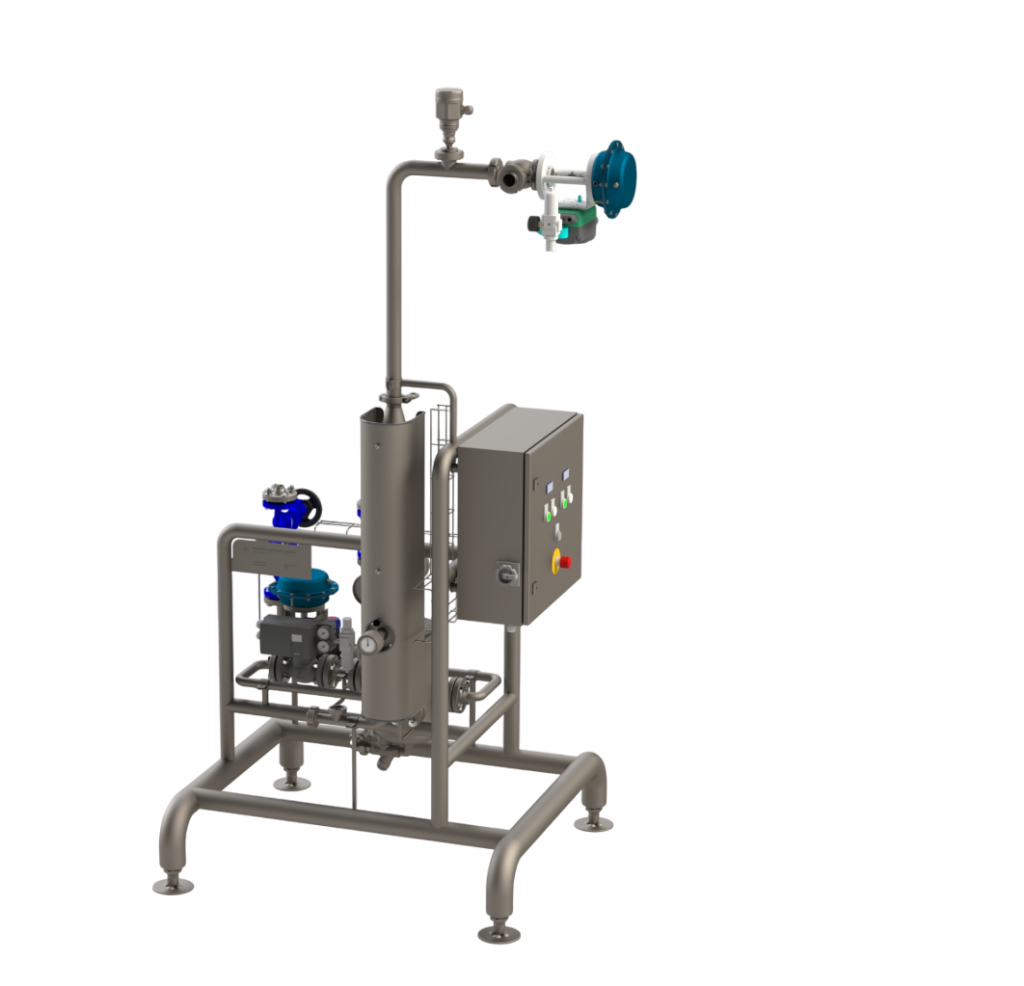

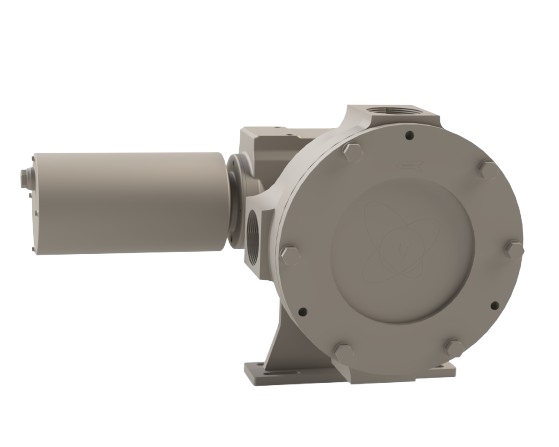

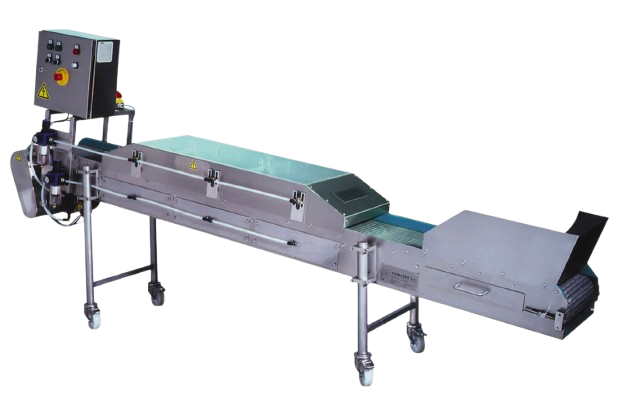

Other machines

The VomaCLEAN is a dry cleaning system for removing powder, starch, and sugar residues from molded gummies and other soft confectionery products. Designed specifically for jelly, nutraceutical, and starch-coated sweets, the system uses high-efficiency air spinners to gently clean the product surface without brushes or rollers.

Its non-contact process ensures product integrity and avoids sticking, deformation, or abrasion. The stainless-steel construction meets hygienic production standards and is easy to maintain with compressed air cleaning. The compact design allows for integration into existing confectionery lines, from pilot-scale setups to high-output plants.

Ideal for manufacturers looking to streamline starch removal, reduce handling, and improve product finish before coating, polishing, or packaging, the VomaCLEAN offers efficient, reliable surface cleaning for molded confectionery.