Precise cooling

Accurate

Stable

Hygienic

Frequently Asked Questions

Feel free to contact us.

Cooling that protects quality

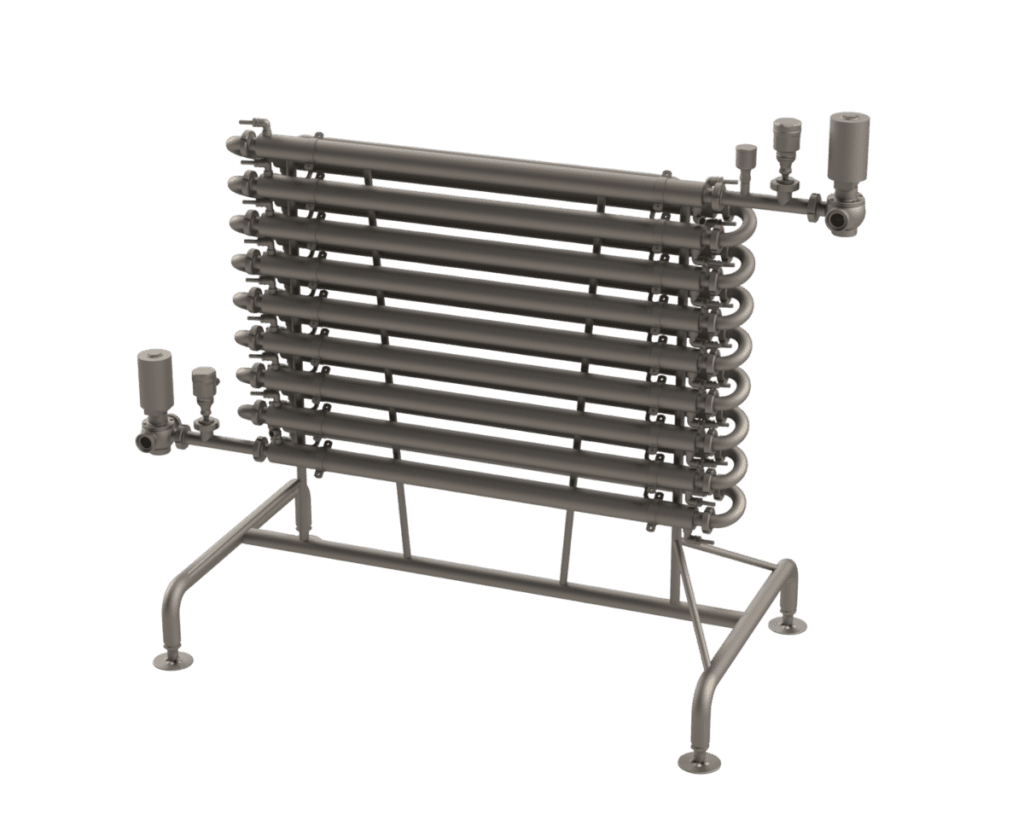

The VomaTEMP cools heat-sensitive confectionery products like marshmallow, jelly, and caramel in a controlled, continuous process. The product flows through static mixers inside double-walled stainless-steel pipes, where cold water circulates through the jacket to remove heat evenly.

This indirect cooling method protects product texture, prevents crystallization, and ensures the right temperature and viscosity for downstream steps like forming, extruding, or aerating.

With no moving parts in contact with the product, the VomaTEMP offers hygienic, low-maintenance operation. It integrates seamlessly into continuous production lines or functions as a stand-alone cooling stage.

Other machines

The VomaTEMP is an inline tubular cooling system for liquid confectionery products such as marshmallow, jelly, caramel, and other sugar-based masses. It uses double-walled stainless-steel pipes with integrated static mixers to ensure uniform product flow and efficient heat exchange.

Cold water circulates through the jacket to reduce temperature without applying mechanical stress. This indirect cooling process helps maintain viscosity and structure, making it ideal for mass flows that require precise temperature control before extrusion, aeration, forming or molding.

The VomaTEMP integrates directly after continuous cookers or mixing units and is available in various pipe diameters and lengths to match your process. With no moving parts in contact with the product, it offers a hygienic, low-maintenance cooling solution for modern food and confectionery lines.

Whether you need to stabilize gelatin masses, syrup-based recipes or whipped products, the VomaTEMP provides consistent, repeatable cooling performance