Lab & Pilot Plants

Specials

VomaCLEAN

VomaFC

VomaEXTRUDE

VomaTHERM

VomaJET

VomaRC

VomaCOAT

VomaSHINE

VomaWHISK

VomaCOOK

VomaTEMP

VomaTAB

VomaDOS

VomaBPS

VomaDISS

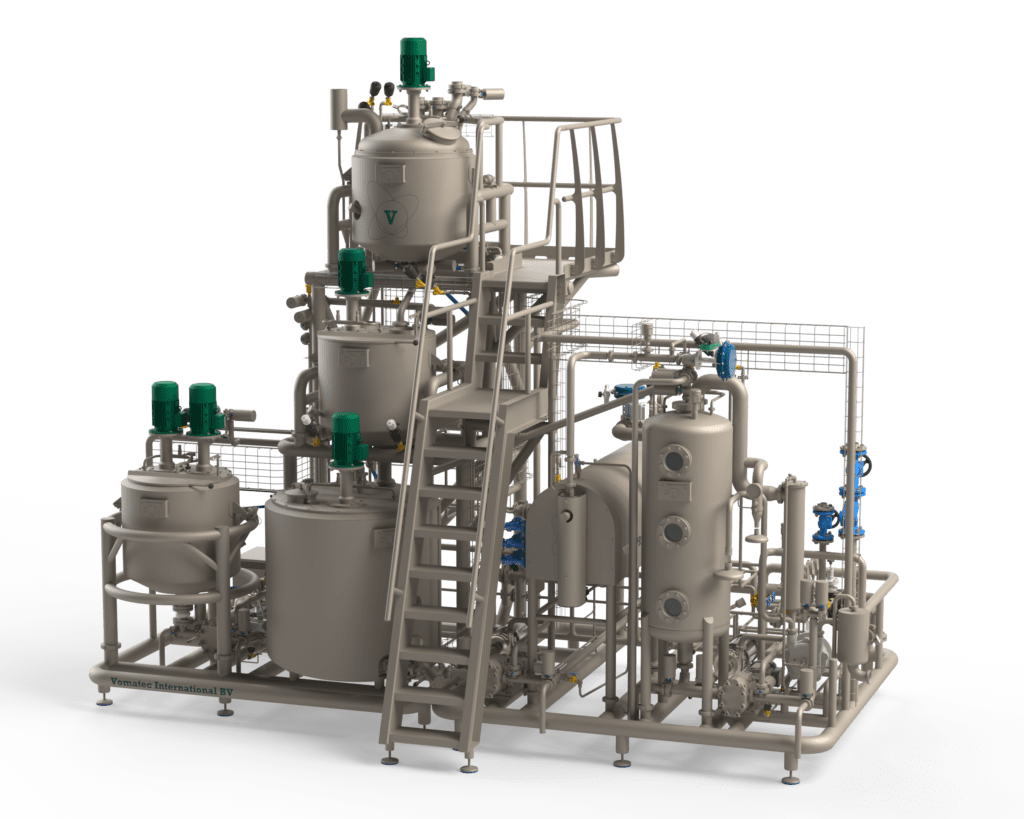

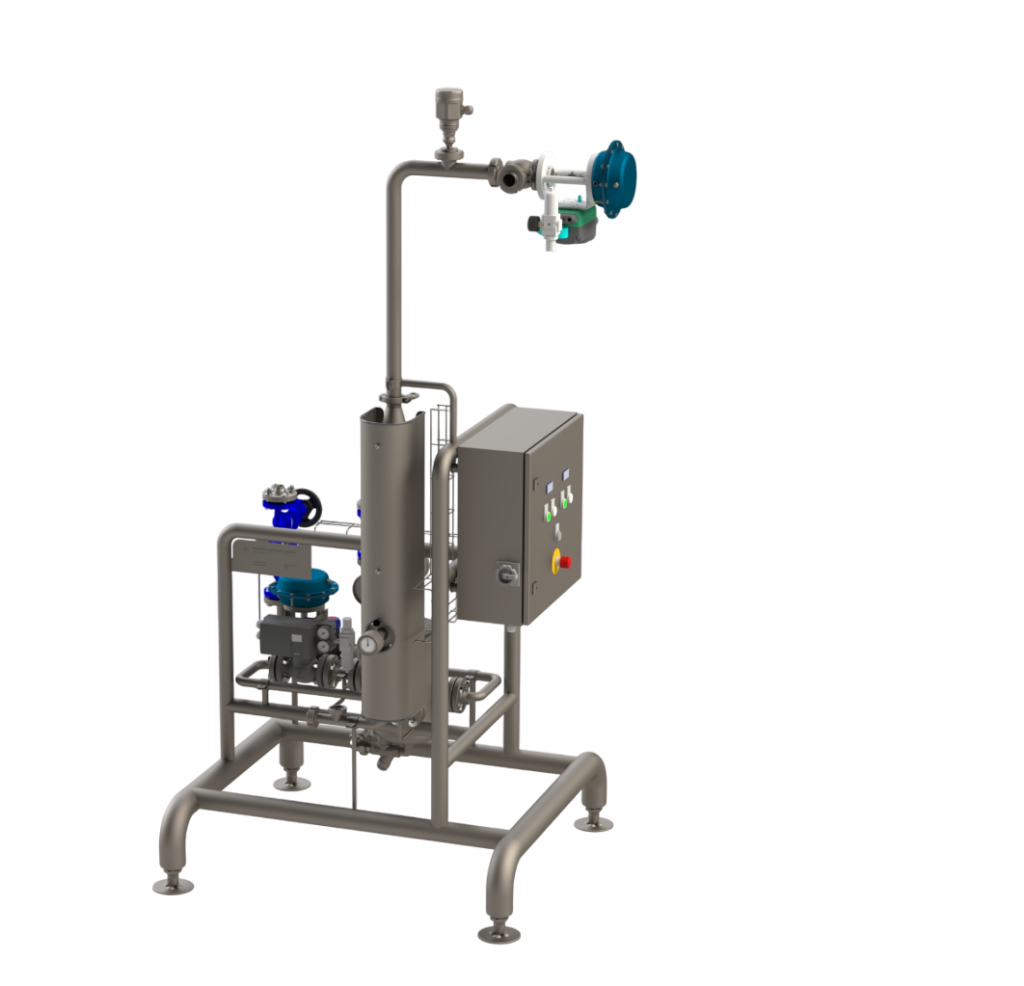

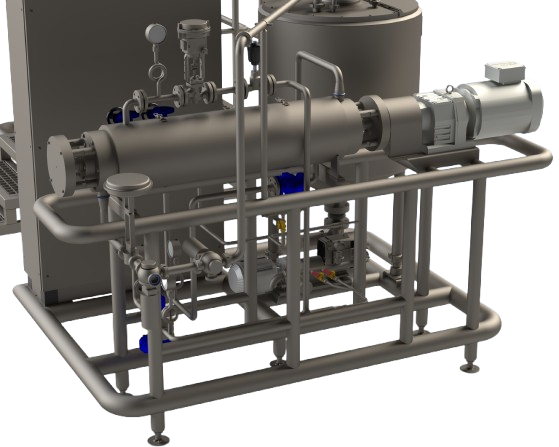

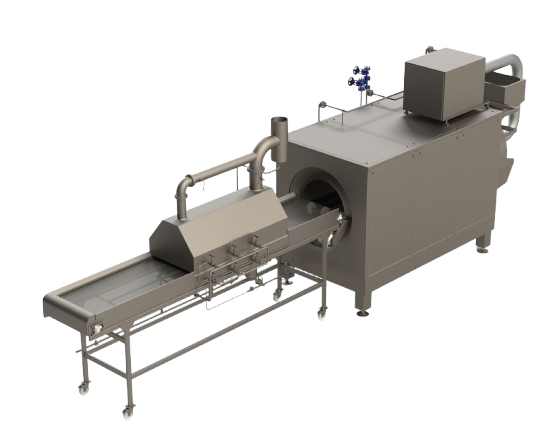

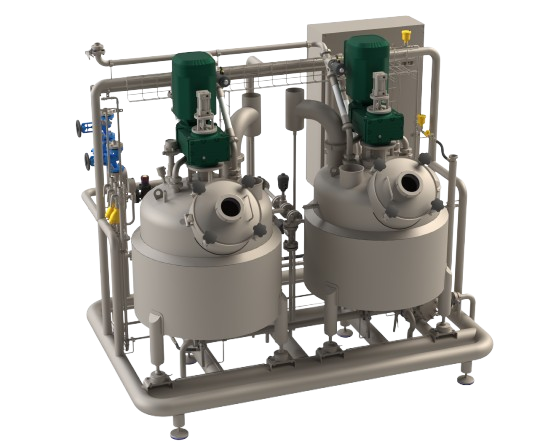

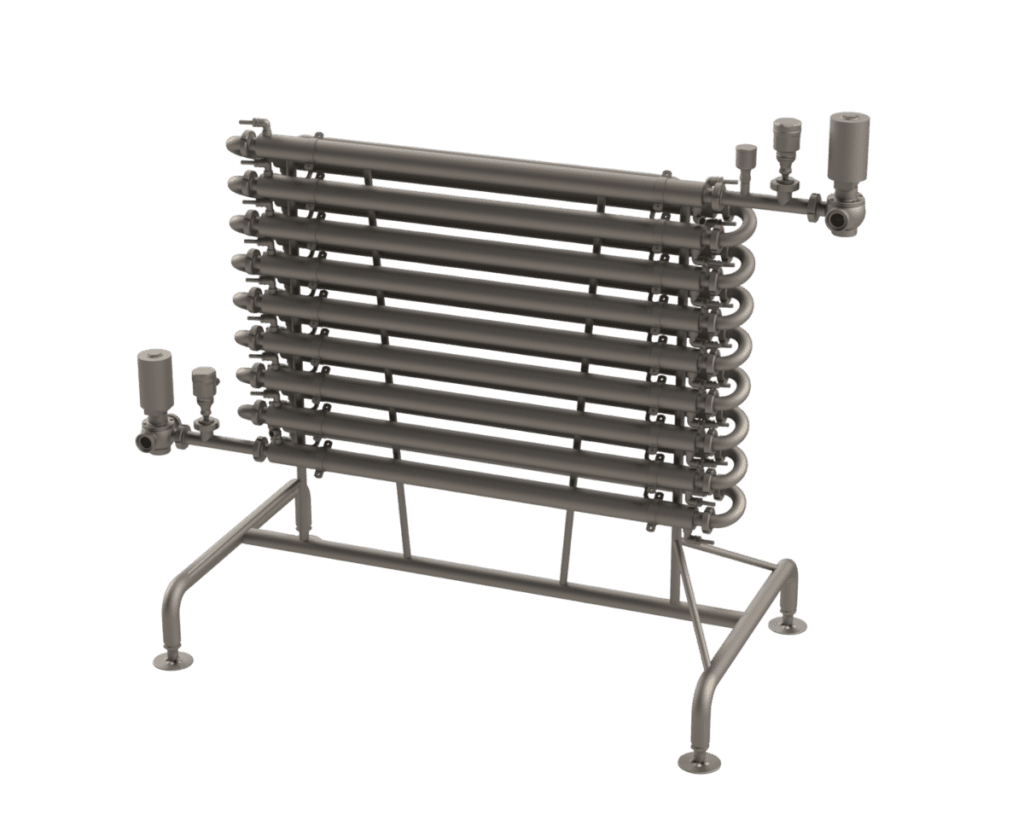

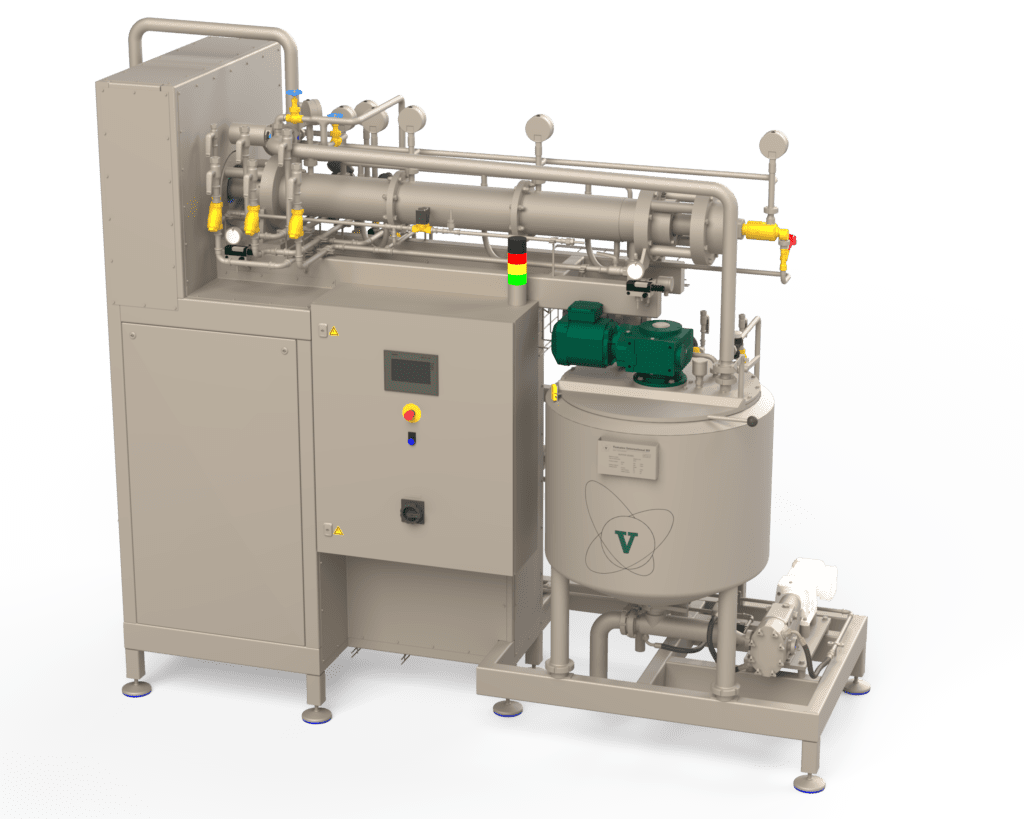

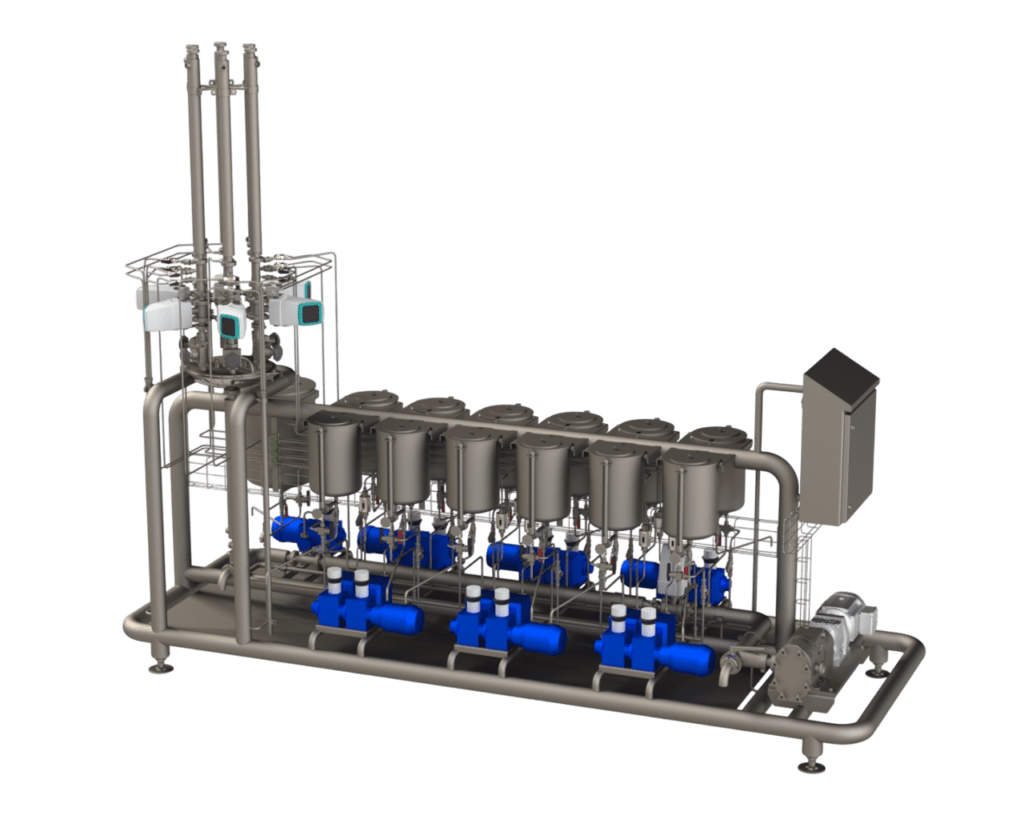

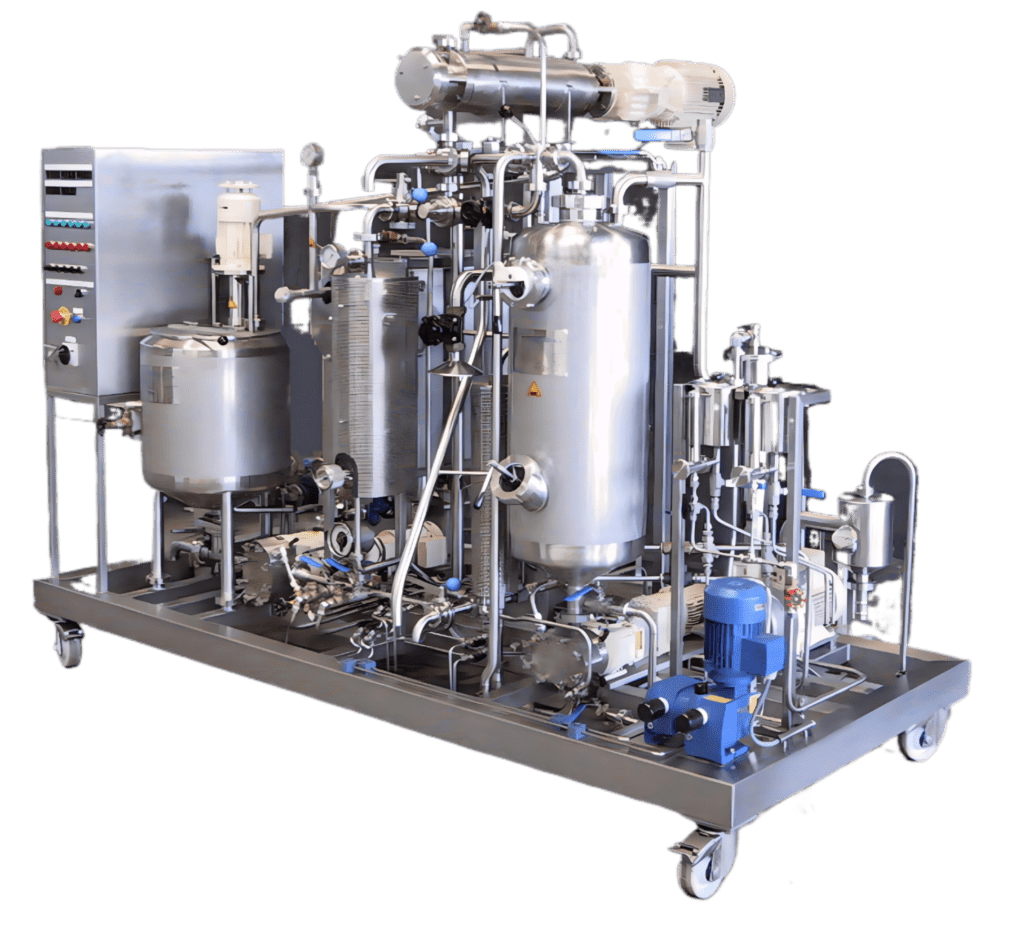

Lab & Pilot plants:

From first trials to scalable success

In confectionery and nutraceutical production, innovation begins at lab scale. Whether testing a new recipe, refining a process, or validating product behavior, lab and pilot plants are essential for developing reliable, scalable manufacturing lines.

These facilities allow manufacturers to test, refine, and validate recipes and processes on a smaller scale, minimizing risks and ensuring consistent quality before moving to full-scale production.

Core benefits

Process Validation: Enables safe, small-scale testing of formulations and parameters in controlled conditions.

Scalable Development: Mirrors full-scale performance for smoother transition from test batch to production.

Cost Efficiency: Minimize waste and optimize production parameters before large-scale implementation.

Supporting innovation with real-world engineering

At Vomatec, we design lab and pilot plant solutions that reflect the performance, hygiene standards and control systems of full-scale production — without compromise. Our modular setups are built to adapt, scale, and integrate easily into your innovation process.

Whether you’re formulating a new product or fine-tuning existing processes, Vomatec gives you the tools to bridge development and production with precision and confidence.

Other categories