Efficient storage for consistent production

Heated

Hygienic

Tailored

Frequently Asked Questions

Feel free to contact us.

Advanced storage solutions

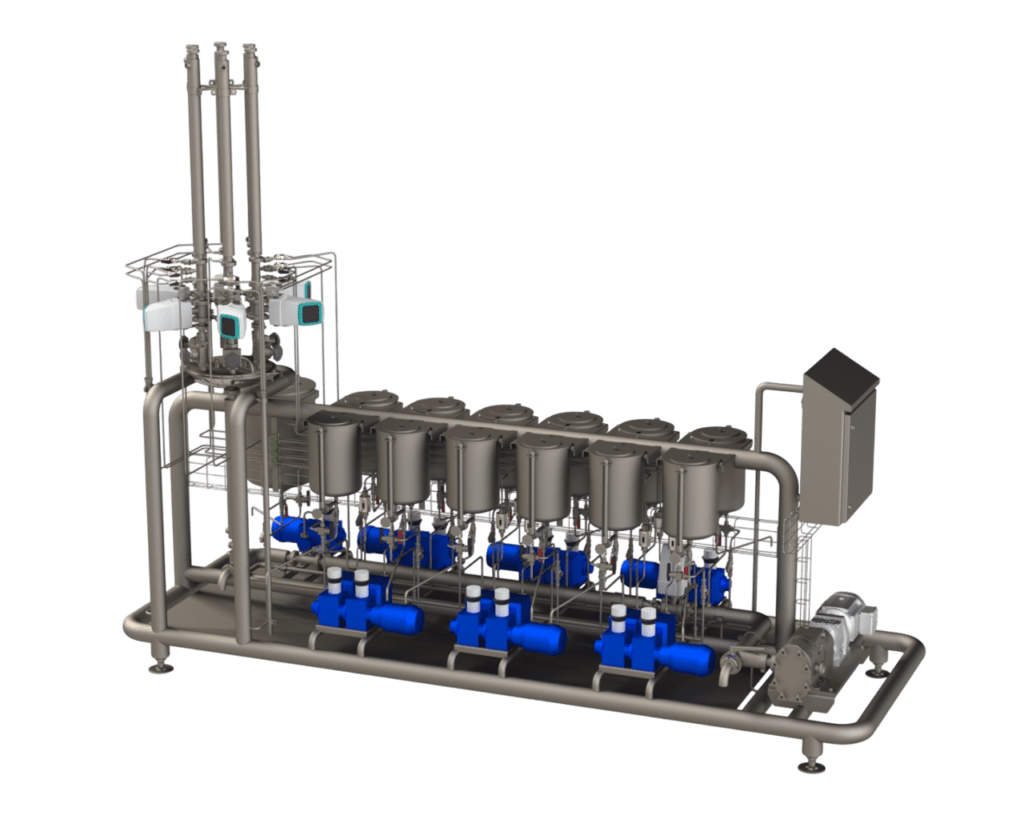

The Vomatec Glucose Tank is built to store liquid glucose and other syrup-based ingredients under optimal conditions. In confectionery and food production, stable syrup quality is critical — fluctuations in temperature or viscosity can affect dosing, mixing and final product texture. That’s why this tank is heated and insulated to maintain consistent temperature and prevent crystallization, even during long holding times.

The tank is made from high-grade stainless steel, with a hygienic, easy-to-clean interior that meets the strictest food safety standards. It supports fast drainage and can be fitted with optional CIP nozzles or level sensors to match your automation level.

Whether you work with small batches or large-volume production, Vomatec offers custom tank sizes and integration options to fit your line. The system can operate as a standalone unit or be linked to continuous cookers, premix stations or dosing systems.

Other machines

The Vomatec Glucose Tank stores liquid glucose, corn syrup and other sugar-based ingredients under precise, temperature-controlled conditions. It prevents crystallization and keeps the product flowable, supporting consistent production in both batch and continuous processes.

This tank integrates easily with continuous cookers, syrup dosing systems or premix units. Insulated walls and optional electric or hot water heating maintain the correct temperature. You can equip the tank with CIP nozzles, level sensors or load cells to match your automation level.

Vomatec offers a wide range of capacities and tailors each tank to your line requirements. With its hygienic stainless-steel construction and smooth internal surfaces, the tank supports quick cleaning and helps you meet strict food safety standards.

Use the Vomatec Glucose Tank to improve syrup handling across applications like gummies, caramels, nougat and nutraceutical jellies. It reduces waste, lowers cleaning time and increases line reliability — all with long-term performance in mind.