Batch Cooking for Confectionery

Consistent

Flexible

Robust

Frequently Asked Questions

Feel free to contact us.

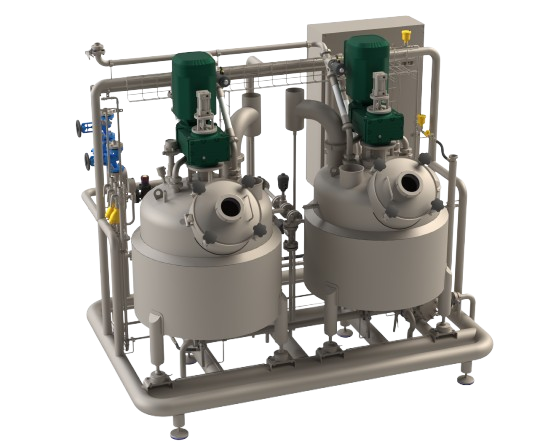

VomaCOOK

The VomaCOOK is a high-performance batch cooker designed to meet the needs of the confectionery industry. Ideal for producing caramels, fudges, and other sugar-based recipes, it ensures precise temperature control and consistent results.

Featuring a durable stainless-steel design, the VomaCOOK provides even heat distribution, preventing product burning and ensuring optimal quality. Its user-friendly interface allows operators to make precise adjustments, streamlining the cooking process and maintaining consistency across batches.

With the ability to handle heat-sensitive ingredients like dairy, the VomaCOOK’s flexible, modular design makes it suitable for both small-scale and large-scale production. Whether integrated into existing production lines or used as a stand-alone unit, it offers efficiency and reliability for manufacturers of all sizes.

The VomaCOOK helps producers reduce waste, improve control over cooking processes, and achieve higher production efficiency — all while maintaining superior product quality.

Other machines

Batch cooker for confectionery production

The VomaCOOK is a batch cooking system designed for the controlled heating of sugar-based and heat-sensitive confectionery masses. It ensures even heat distribution and precise temperature control, making it ideal for applications like caramel, fudge, nougat, and other delicate products.

Equipped with advanced heat transfer technology, the VomaCOOK prevents burning and preserves the structure of the product. Its hygienic stainless-steel construction and simple design make it easy to clean and maintain, reducing downtime and operational costs.

The VomaCOOK is available in various sizes, making it suitable for both small-scale and large-scale production. It’s an energy-efficient solution that meets the demands of modern confectionery production. Whether you’re looking to optimize your current processes or scale up to higher capacities, the VomaCOOK delivers consistency and reliability.

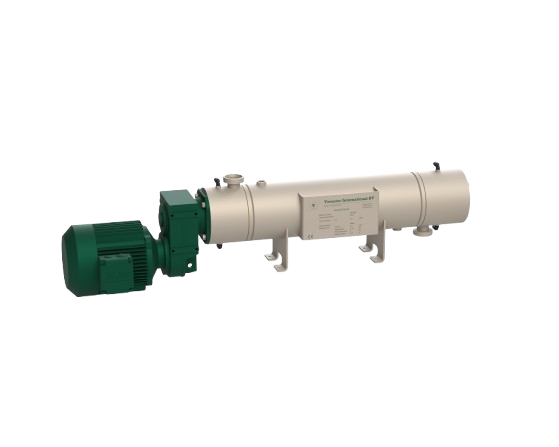

For manufacturers seeking continuous cooking solutions with higher throughput, the VomaDISS continuous cooker offers scalable performance and tighter process control.