Precision and reliability in scraped surface heat exchange

Tailored

Controlled

Removable

Frequently Asked Questions

Feel free to contact us.

Redefining heat exchange for confectionery excellence

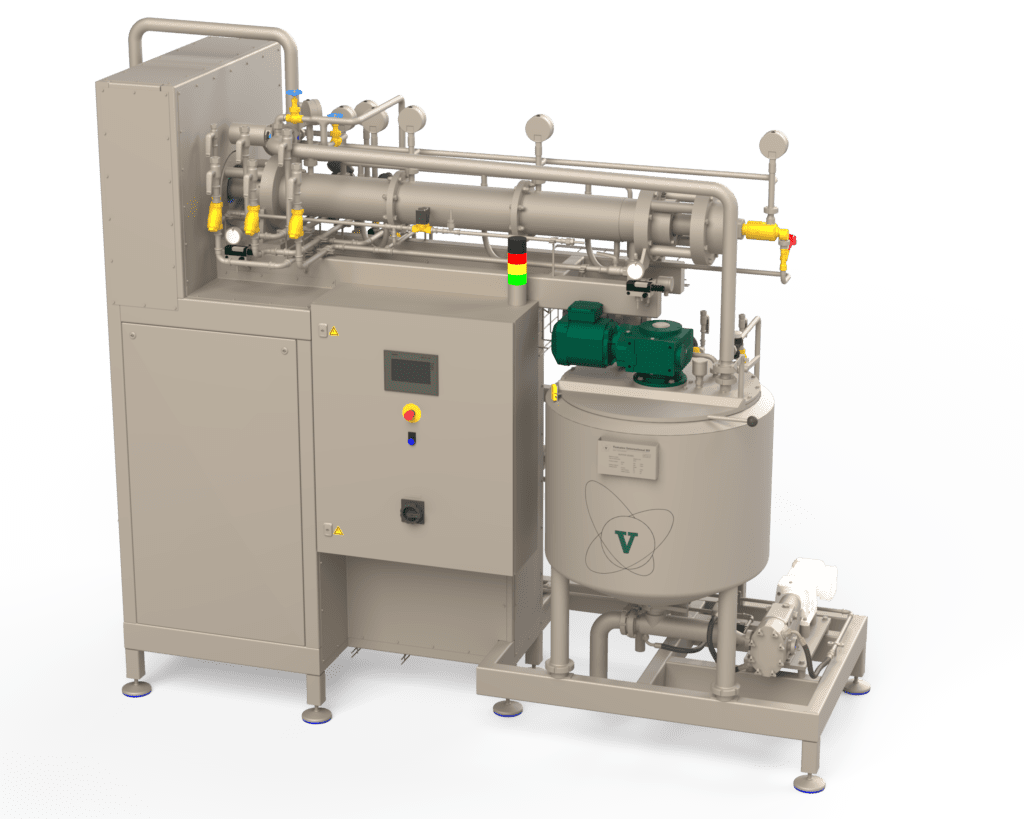

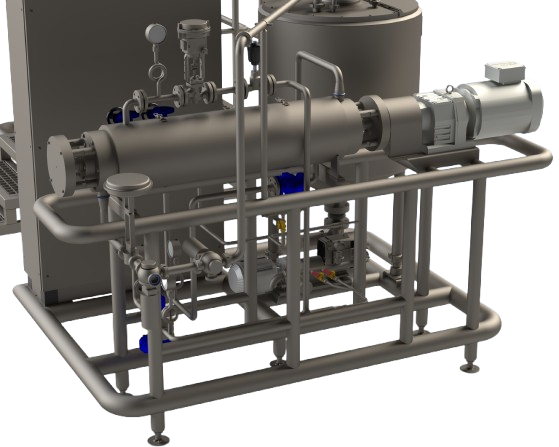

The VomaRC is a high-performance scraped surface heat exchanger for demanding confectionery processes. Ideal for caramel, nougat, milk-based and heat-sensitive recipes, it delivers even heating and consistent results without scorching.

Thanks to its removable product tube and durable PEEK scrapers, maintenance is simple and efficient, especially when working with crystallizing ingredients.

Built for both small and large-scale production, the VomaRC fits into new or existing lines, with hygienic design and robust construction that maximize uptime and product quality.

Other machines

The VomaRC scraped surface heat exchanger by Vomatec is the ideal solution for confectionery producers seeking precision, efficiency, and reliability. Designed to handle heat-sensitive and viscous products such as caramel, nougat, fondant, and milk-based masses, the VomaRC ensures consistent results without compromising product quality.

Equipped with a removable product tube, the VomaRC offers unmatched ease of maintenance, allowing for quick part replacement and minimal downtime. Its durable PEEK scrapers and advanced heat transfer technology prevent product scorching and ensure even heating throughout the cooking process. This makes it the perfect choice for manufacturers looking to optimize their production of delicate confectionery products.

The VomaRC seamlessly integrates into any production line, whether for small-scale operations or large-scale manufacturing. Its hygienic design and robust construction ensure long-term reliability while minimizing operational costs. By choosing the VomaRC, confectionery producers can achieve greater efficiency, reduce waste, and maintain the highest product quality standards.